Area: Key Technologies

DIGITEX-PLAS

This project involving 8 companies (4 textile companies and 4 plastics/toy companies) and the AIJU and AITEX technology centres aims to research and develop new processes and products enabling rationalisation of digital printing on textiles and plastic materials. [...]

Read More... from DIGITEX-PLAS

View moreFinanced

Cartridge wadding – PVA-based biodegradable and ecological cartridge wadding

The main aim of the project is to design, manufacture and launch on the market an innovative and environmentally friendly shotgun cartridge with water-soluble and biodegradable components (the wadding). [...]

Read More... from Cartridge wadding – PVA-based biodegradable and ecological cartridge wadding

View moreFinanced

NANOCARB – Use of nanocompounds based on carbon nanotubes and nanofibres for obtaining conducting polymers of high added value for diverse sectors

AIJU, in collaboration with AIMPLAS, have jointly worked on this project for two years with the aim of improving competitiveness of various technical thermoplastics of application to products with electric and electronic components of high added value, through the addition of conducting nanoparticles. [...] View more

Financed

EmiToy – Improvement of electromagnetic behaviours of electronic toys through the development of plastic formulations with carbon nanofibre conductors

This project develops new light absorbents, of broad response against electromagnetic interference (EMI) that can be made at a competitive price and be processed by traditional techniques, avoiding in this way the problems associated with these interferences. [...] View more

Financed

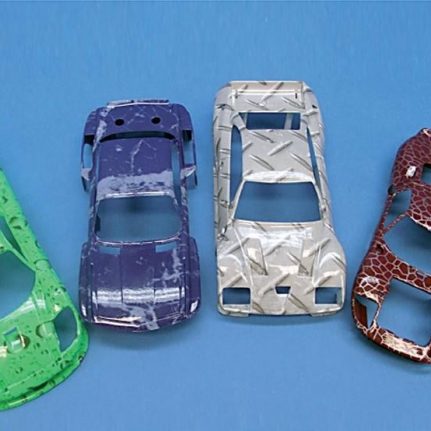

DecoraToy – Customised decoration of toys

Toy industry trends show that products are increasingly required with a higher degree of customisation in shorter production times. Improvement in the techniques of decoration/finishing of items largely facilitates the work involved in solving technical problems and costs to satisfy these trends. [...]

Read More... from DecoraToy – Customised decoration of toys

View moreFinanced

PLAITEC II – Technology cooperation platform for applying innovative technologies in childhood

This project aims to consolidated and amplify the Technology Platform for Innovation in Childhood, created in 2008, through the construction of its successor PLAITEC II. The activities previously started will be allowed to continue and new and better results are expected. [...] View more

Financed

IBE-RM: Ibérica Rapid Manufacturing

This project undertakes to break down these barriers through development of new tools, technologies and methods, making our technology and productive environment more competitive. The project is led by ASCAMM and has 27 participant members that complement the knowledge chain for optimum R&D. [...]

Read More... from IBE-RM: Ibérica Rapid Manufacturing

View moreFinanced

Development of new materials for selective laser sintering for new technological applications (MATSINTER)

The aim of this project is to develop new formulations of materials with various properties for processing by SLS: plastics with electrical conductivity, ceramic powder, plastics with new contents, with biodegradable properties, etc. [...] View more

Financed

Investigation of a new thermoplastics transformation system, assisted by ultrasound, for application to high productivity extrusions processes (ULTREX)

The main aim of the project is to improve the extrusion process through the introduction of a controlled ultrasonic vibration assistance process. [...] View more

Financed

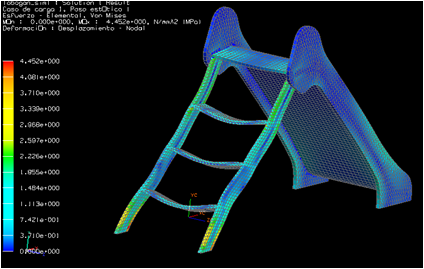

OPTIPARC: Development and validation of tools that optimise design in activity games for domestic indoor or outdoor use

Given that the most important toys are those called activity toys for indoor and or outdoor domestic use, this project addressed the issue by proposing the use of advanced computer-aided engineering (CAE) simulation tools that enable optimising designs and adapting the design to expectations through use of tools that enable verification of ergonomics, avoiding excessive thickness, proposing improvements in manufacture, optimising design for each type of material to be used, improving the quality of the products, suitability and durability, and enabling improvement of the final product from the design stage. [...] View more

Financed