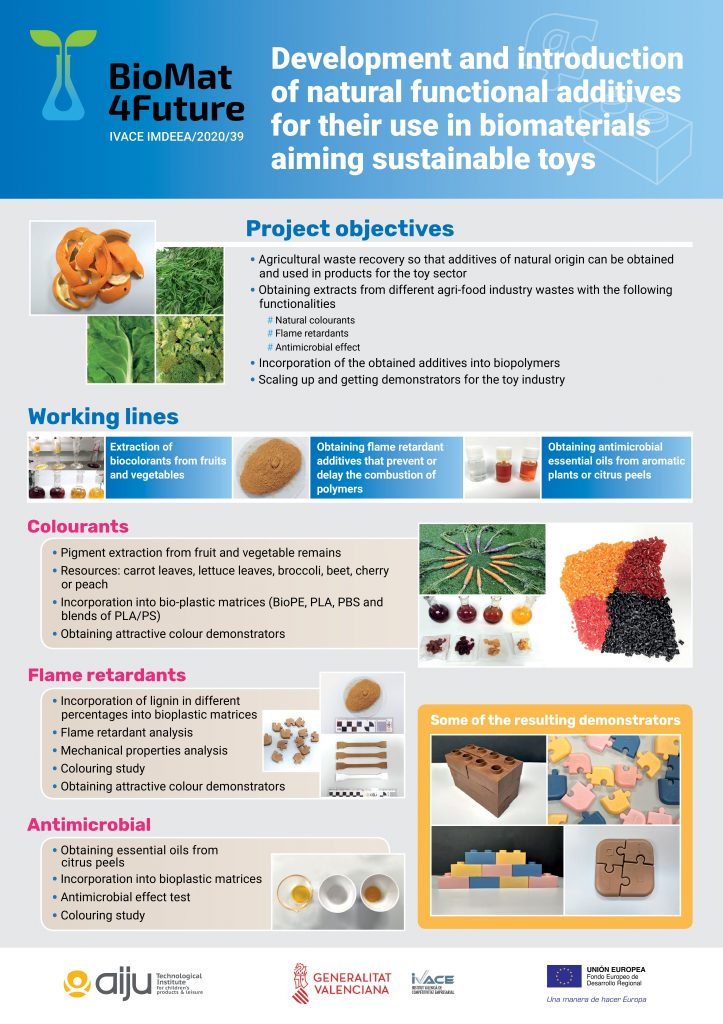

Development and introduction of natural functional additives for their use in biomaterials aiming sustainable toys: – Extraction of biocolorants from fruits and vegetables – Obtaining flame retardant additives that prevent or delay the combustion of polymers – Obtaining antimicrobial essential oils from aromatic plants or citrus peels

Carbon human emissions have increased among 33% & 130% in the last decades regarding the last 800,000 years from burning fossil fuels. The regulation in Europe asks manufacturers to implement sustainable alternatives but it can be hard for them to change their feedstock materials, especially when dealing with polymeric materials. Bioplastics without additives are nor viable. The development of new biomaterials matches with the development of additives of bio-based basis in sufficient amount and at acceptable costs. Are we able to achieve natural functional additives extracted from agricultural waste to provide several functionalities to the bioplastics were they are inserted?

The BioMat4Future project has achieved the development and introduction of natural functional additives for their use in biomaterials aiming sustainable toys. With this aim, first the project proceed to the Pigment extraction from fruit and vegetable remains from several resources: carrot leaves, lettuce leaves, broccoli, beet, cherry or peach. Then, we incorporated them into bio-plastic matrices (BioPE, PLA, PBS and blends of PLA/PS). Finally, we obtained attractive coloured toy demonstrators.

Regarding the flame retardants, it was proceeded to the incorporation of lignin in different percentages into bioplastic matrices. Then, we carried out the flame retardant analysis as well as the mechanical properties one. After the colouring study, attractive coloured demonstrators were achieved.

Finally, to achieve the functional antimicrobial functionality, essential oils from citrus peels was obtained. After their incorporation into bioplastic matrices, the antimicrobial effect test were performed. As in previous cases, the tasks ended with the colouring study. With this project, AIJU has provided solutions to the requirements of its industry as the RTO has been doing it during the last 35 years.

This project is has been supported by IVACE under Ref IMDEEA/2020/39 and 50% co-funded through the Valencian Community operative program FEDER 2014-2020. All, the results of the project objectives and the results of the analysis performed, can be checked at the following documents: