Area: Advanced Manufacturing Processes

Chemical markers to improve traceability of children’s products as a solution to anti-counterfeiting – TRACE4FAKE

Is it possible to manufacture children's products using anti-counterfeiting materials, and is it possible to do so while avoiding any toxicological risk to the user?

The implementation of chemical markers in the materials used for the manufacture of the children's product allows a product to be traced quickly and economically, through photoluminescent properties, among others, which can be modulated according to the specific needs of each company and/or product.

Development of high-frequency communications devices using advanced additive manufacturing and coating technologies – CAFTAM

Current radio communication systems are dealing with the progressive saturation of the electromagnetic spectrum which, together with increasing bandwidth requirements (transmission speeds), is forcing systems to migrate to higher frequency bands.

View more

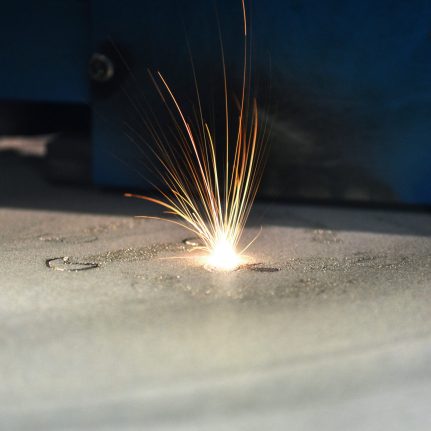

GVA 2021 I+D New materials of Metal additive manufacturing

The objective of this research line is to be able to offer companies new opportunities for the use of additive manufacturing (AM) technologies, through the development and application of new materials for AM.

View more

New EDM electrodes manufactured with electrically conductive materials by Additive Manufacturing – EDM Additive

Reduce lead times and costs in the manufacturing of electrodes can highly contribute to improve the SMEs competitiveness. Moreover, additive technologies allow the manufacturing of more complex electrodes that can boost the manufacturing of more creative moulds and designs.

View more

SAMT SUDOE “Spread of Additive manufacturing (AM) and advanced materials Technologies for promoting industrial KET (Key Enabling Technologies) in plastic processors and mould industries within SUDOE space –SAMT SUDOE”

Development of formulation to reduce the effect of PAHs in the raw materials of child products.

USERM – IMPROVING TRADITIONAL PROCESSES THROUGH THE SEARCH AND INCORPORATION OF NEW RAPID MANUFACTURING APPLICATIONS

TUSACT – Adhesive technologies in sectors with high technology component

Read More... from TUSACT – Adhesive technologies in sectors with high technology component

View more

ADDITIMOULD – Development of nanocomposite moulds for short series of injection moulding through additive manufacturing

BOND-CONTROL: Inspection and evaluation of adhesive bonds in compound materials for quality control