Low-cost robotic developments for manufacturing sectors – MANUBOT

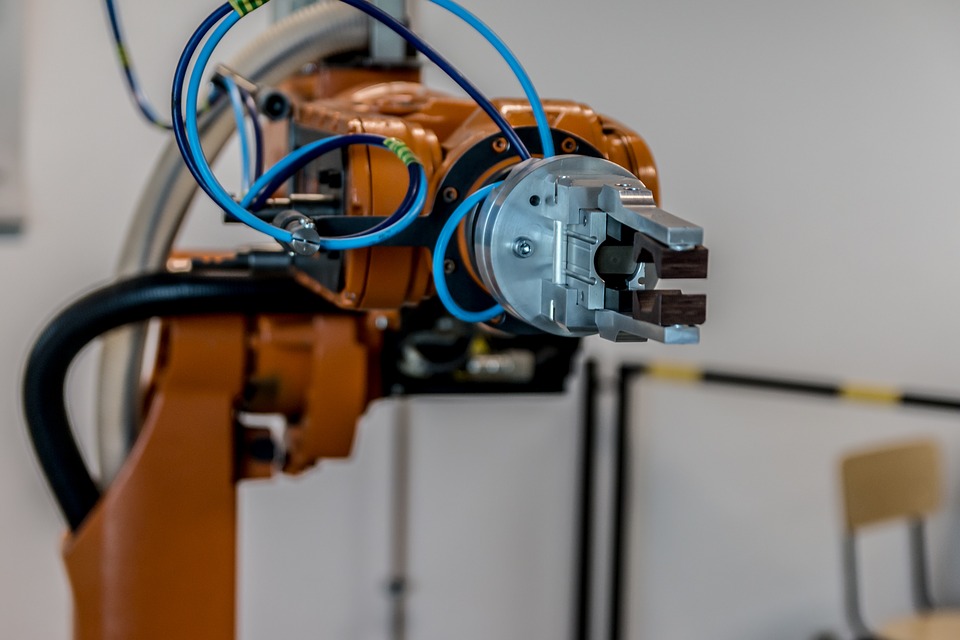

The main objective of this project is to develop low-cost robots for use in the automation of manufacturing processes in the toy sector, dedicated to the manufacture of thermoformed plastic parts by means of blowing and/or rotomoulding processes, or in other similar sectors. The development of these robots is intended to provide reliable automation solutions that can be introduced into sectors that currently still have many technical and economic difficulties when it comes to automating processes that have traditionally been done manually, for two main reasons:

Either no systems for automation and robotization have been developed that meet the needs of the sector.

Or the systems that are on the market are excessively expensive and do not fully meet the necessary requirements.

These low-cost robots will be designed to automate secondary processes in which it is not possible to justify the initial investment implicit in process automation involving the use of conventional industrial robots, due to their high cost.

The intention is also to continue developing previous lines in which we have been working on the development of sensor technologies and tools that make it possible to establish collaborative man-machine working environments aimed at automating plastic part deburring processes. Based on the results of the ROBINT project, a collaborative project that was funded by IVACE in 2016, the aim is to continue moving forward along the lines set out by the results obtained in that project. That project managed to implement a pilot plant that is currently at the TRL5 level, and with the development that has been proposed this year, we intend to continue upgrading the pilot plant until it reaches at least the TRL6 level.

To achieve that, we are proposing the development of new scanning systems which make it possible to digitize and extract information to generate trajectories for an anthropomorphic robot in real time so that it can perform such processes as the deburring or machining of plastic parts manufactured using blowing or rotomoulding processes. In addition, we are also considering the evolution or development of new tools that allow the system to be more flexible when carrying out deburring and machining processes.

Project results:

Through the implementation of the project we hope to implement a robotic cell for surface treatment and machining, allowing the automation of manufacturing processes involving thermoplastic materials. The following developments will be carried out within the framework of the project:

– Development of a low-cost Cartesian robot.

Project subsidised by IVACE, the Valencian Institute for Business Competitiveness of the Regional Government of Valencia, 50% co-financed through the FEDER Operational Programme of the Valencian Community 2014-2020, under file IMDEEA/2018/96

- Start date: January 2018.

- Duration: 12 months

- Status: In process

- File No: IMDEEA/2018/96. Amount granted: € 106,921.29

SECTORS OF APPLICATION

- Industrial processes

TECHNOLOGICAL AREAS

- Robotics

- Process automation

IVACE PROGRAMME:

- Programme: INDIVIDUAL R&D

CONTACT COORDINATOR:

- Contact: Julian Fortés

- Telephone: 965554475

- e-mail: julianfortes@aiju.es